Conveyor Systems: Essential Features for Safety, Efficiency, and Sustainability

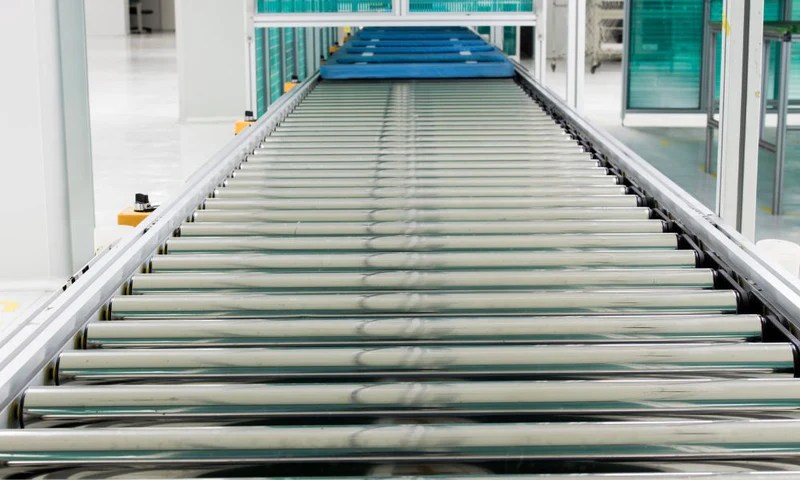

Conveyors should be equipped with which of the following – Conveyor systems are the backbone of many industries, facilitating the smooth and efficient movement of goods. But beyond basic functionality, the features that equip these systems play a crucial role in ensuring safety, optimizing performance, and minimizing environmental impact. This exploration delves into the key aspects that make a conveyor system truly effective and reliable.

From robust safety features that prevent accidents to energy-efficient designs that reduce environmental footprint, each element contributes to the overall effectiveness and longevity of a conveyor system. Understanding these features empowers you to make informed decisions when choosing or upgrading your conveyor equipment.

Maintenance and Durability

Conveyor systems are vital for many industries, ensuring efficient material handling and production. Their reliability and longevity depend heavily on regular maintenance practices. Proper maintenance not only extends the lifespan of conveyors but also minimizes downtime, reduces operating costs, and enhances safety.

Factors Contributing to Conveyor Durability

Conveyor durability is influenced by various factors, including robust construction materials, corrosion resistance, and lubrication systems. These features minimize wear and tear, extending the lifespan of the equipment.

- Robust Construction Materials:Choosing high-quality materials like steel, stainless steel, or aluminum with appropriate strength and durability is crucial. These materials can withstand heavy loads, impact, and abrasion, ensuring long-term performance.

- Corrosion Resistance:Conveyor components exposed to harsh environments require corrosion-resistant materials or coatings. Stainless steel, galvanized steel, or powder coatings provide protection against rust and corrosion, extending the life of the system.

- Lubrication Systems:Regular lubrication of bearings, gears, and other moving parts is essential to reduce friction and wear. Proper lubrication minimizes heat generation, extends component life, and ensures smooth operation.

Benefits of Different Maintenance Practices

Different maintenance practices have varying impacts on conveyor durability. Here’s a comparison of common practices and their benefits:

| Maintenance Practice | Benefits |

|---|---|

| Regular Inspections | Early detection of wear, damage, or potential issues, allowing for timely repairs and preventing major breakdowns. |

| Preventive Maintenance | Scheduled maintenance tasks like lubrication, cleaning, and component replacement reduce wear and tear, extending the life of the conveyor system. |

| Predictive Maintenance | Using sensors and data analysis to predict potential failures, allowing for proactive maintenance and minimizing downtime. |

Customization and Adaptability: Conveyors Should Be Equipped With Which Of The Following

Conveyor systems are designed to move materials efficiently, but their effectiveness can be significantly enhanced by tailoring them to specific application needs. Customization ensures that conveyors are optimized for the unique requirements of each task, resulting in increased productivity, reduced downtime, and improved safety.

Customization Options and Benefits, Conveyors should be equipped with which of the following

Customization options for conveyors allow for flexibility and adaptability, enabling them to handle a wide range of materials and operating environments. Here are some common customization options and their associated benefits:

| Customization Option | Benefits |

|---|---|

| Modular Design | Modular design allows for easy assembly, disassembly, and reconfiguration of conveyors. This flexibility enables quick adjustments to accommodate changes in production lines or material handling needs. |

| Adjustable Speed | The ability to adjust conveyor speed allows for optimization based on material type, weight, and desired throughput. This ensures efficient material movement while minimizing damage to delicate products. |

| Interchangeable Components | Interchangeable components, such as belts, rollers, and drive systems, enable easy replacement and repair, minimizing downtime. This also allows for adaptation to different material handling requirements, such as handling different sizes or shapes of materials. |

| Customizable Belt Materials | Conveyor belts can be made from various materials, such as rubber, plastic, metal, or fabric, to handle specific materials and environments. This ensures durability and compatibility with the materials being conveyed. |

| Specialized Conveyor Types | There are various specialized conveyor types, such as belt conveyors, roller conveyors, chain conveyors, and screw conveyors, each suited for different applications. This allows for selecting the most efficient conveyor for the specific material handling needs. |

Final Review

The success of a conveyor system lies in its ability to seamlessly integrate safety, efficiency, and sustainability. By prioritizing these features, you can optimize your operations, minimize downtime, and ensure a responsible approach to material handling. As technology advances, we can expect even more innovative features to emerge, further enhancing the performance and environmental footprint of conveyor systems.