What Causes Pressure Increase During Tank Leak Tests?

What causes pressure to increase in tank during leak test sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. Imagine a scenario where you’re conducting a leak test on a sealed tank, but instead of seeing pressure drop as expected, it inexplicably rises.

This unexpected pressure increase can be a perplexing phenomenon, raising questions about the integrity of the tank, the testing equipment, and even the surrounding environment. This article delves into the intricate world of pressure dynamics during leak testing, exploring the common culprits behind pressure increases and offering practical insights for troubleshooting and prevention.

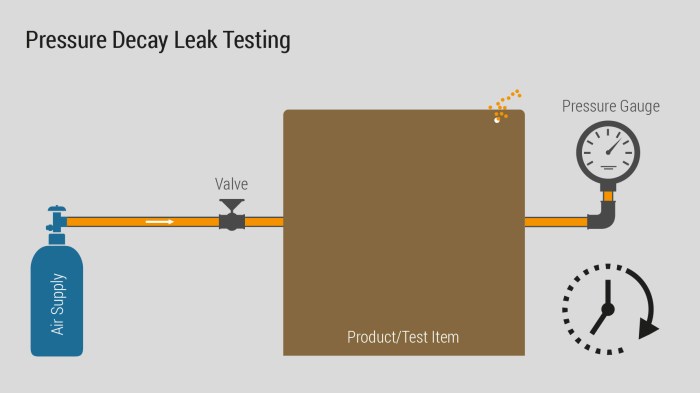

The pressure within a sealed container is a delicate balance, influenced by factors like the volume of the container, the properties of the testing medium, and the presence of any external forces. During a leak test, the goal is to observe a gradual pressure decrease as the testing medium escapes through any potential leaks.

However, a pressure increase can signal a different story, suggesting that something is preventing the pressure from dropping or even actively pushing it higher. This can stem from external sources like atmospheric pressure changes, internal sources like reactions within the tank, or even issues with the leak testing equipment itself.

Understanding the interplay of these factors is crucial for accurately interpreting leak test results and ensuring the safety and integrity of the tested system.

Understanding Pressure Dynamics in a Tank During Leak Testing

Pressure dynamics play a crucial role in leak testing, influencing the accuracy and reliability of the test results. Understanding how pressure behaves within a sealed container during testing is essential for interpreting the results and ensuring the integrity of the system.

Pressure and Volume Relationship, What causes pressure to increase in tank during leak test

Pressure and volume are inversely proportional within a sealed container, meaning that as the volume decreases, the pressure increases, and vice versa. This relationship is governed by Boyle’s Law, which states that the product of pressure and volume remains constant at a constant temperature.

P₁V₁ = P₂V₂

Where:

- P₁ is the initial pressure

- V₁ is the initial volume

- P₂ is the final pressure

- V₂ is the final volume

This principle is fundamental to leak testing. When a tank is pressurized, the air or gas inside exerts a force on the container walls. If there’s a leak, the volume of the container effectively decreases, causing the pressure to rise.

The rate of pressure increase can be used to determine the severity of the leak.

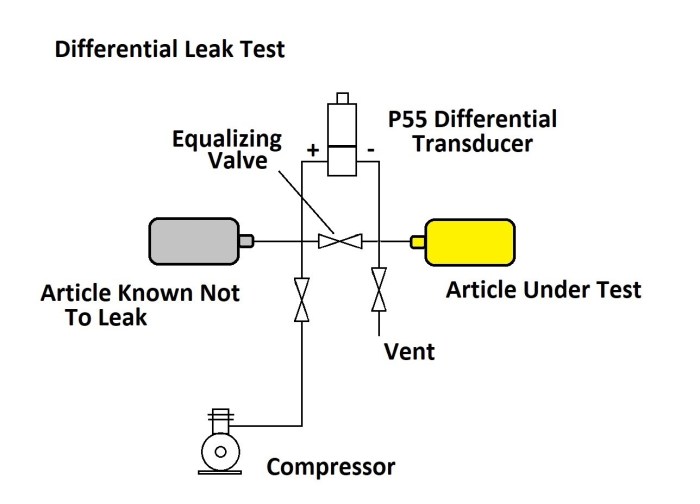

Pressure Equalization

Pressure equalization is the process of balancing the pressure inside a container with the pressure outside. During leak testing, pressure equalization is crucial for accurate results.

- Initial Pressure Equalization:Before pressurizing the tank, it’s important to ensure the internal pressure is equal to the external pressure. This eliminates any pressure differences that could influence the leak test results.

- Pressure Equalization During Testing:During the leak test, the pressure inside the tank should be maintained at a constant level. If the pressure inside the tank drops due to a leak, it needs to be replenished to maintain a consistent testing environment.

Testing Medium

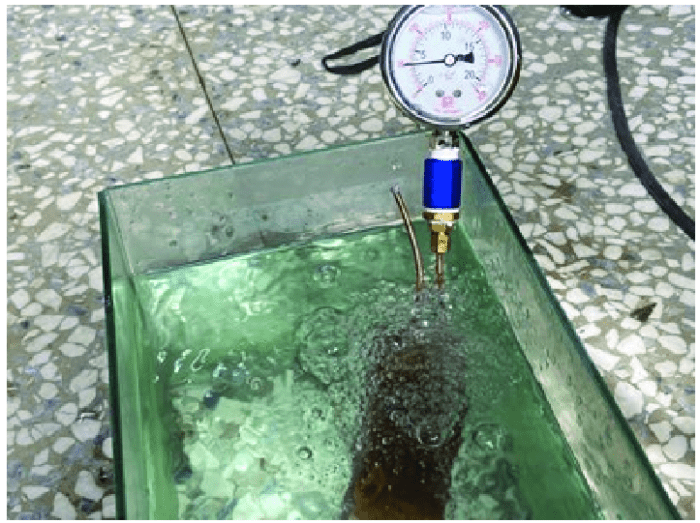

The choice of testing medium, whether air, water, or gas, significantly influences pressure dynamics.

- Air:Air is a common testing medium due to its availability and ease of use. However, air can be compressible, meaning its volume can change under pressure. This compressibility can impact pressure readings during leak testing, especially if the leak is small.

- Water:Water is an incompressible fluid, making it a more accurate testing medium for detecting small leaks. However, water can be corrosive, and its use may not be suitable for all systems.

- Gas:Gas is another common testing medium, offering advantages like high sensitivity and ease of application. The choice of gas depends on the specific requirements of the test, such as the pressure range and the type of material being tested.

Troubleshooting Pressure Increase Issues

A steady pressure increase during a leak test can be a frustrating issue, but with a methodical approach, you can identify and address the problem.

Common Troubleshooting Steps

Here are some common troubleshooting steps to help you identify and address pressure increase issues during leak testing.

- Inspect the Test Setup:Start by examining the entire test setup. Check for any loose connections, leaks in the pressure lines, or faulty valves. Look for any signs of damage or wear on the equipment.

- Verify Pressure Gauge Accuracy:Ensure the pressure gauge is accurate and calibrated. A faulty pressure gauge can lead to inaccurate readings, making troubleshooting difficult. You can use a calibrated pressure gauge to verify the accuracy of the one you’re using.

- Monitor Pressure Over Time:Track the pressure increase over time. Is it a steady, gradual increase, or is it sudden and erratic? The rate of pressure increase can provide clues about the source of the problem.

- Isolate the Test Object:Disconnect the test object from the pressure source and observe the pressure gauge. If the pressure continues to rise, the issue is likely within the test setup.

- Investigate the Test Object:If the pressure stabilizes when the test object is disconnected, the problem might be with the test object itself. Inspect the object for any leaks, cracks, or other defects.

Using Pressure Gauges and Other Monitoring Equipment

Pressure gauges are essential tools for diagnosing pressure increase issues. They allow you to monitor the pressure in the tank and track changes over time.

- Pressure Gauges:Use a pressure gauge to measure the pressure in the tank and monitor the rate of pressure increase.

- Pressure Transducers:Pressure transducers are electronic sensors that convert pressure into an electrical signal. They can provide a more accurate and continuous reading of pressure than a traditional pressure gauge.

- Data Loggers:Data loggers can record pressure readings over time, allowing you to analyze the pressure trends and identify potential problems.

Documentation and Record-Keeping

Maintaining accurate documentation is crucial for troubleshooting pressure increase issues.

- Record Test Parameters:Document the test parameters, including the initial pressure, the rate of pressure increase, and the time the test was conducted.

- Note Observations:Record any observations made during the test, such as any unusual noises or changes in the pressure gauge readings.

- Document Troubleshooting Steps:Keep a detailed record of the troubleshooting steps taken, including the results of each step.

Accurate and comprehensive documentation helps you understand the problem, identify potential causes, and track your progress in resolving the issue.

Last Point: What Causes Pressure To Increase In Tank During Leak Test

Navigating the complexities of pressure dynamics during leak testing requires a methodical approach. By carefully analyzing the leak test setup, identifying potential sources of pressure increase, and implementing best practices, we can mitigate the risk of unexpected pressure fluctuations and ensure accurate and reliable test results.

Remember, a pressure increase during a leak test is not always a cause for alarm, but it does warrant investigation. Through a combination of understanding, vigilance, and appropriate troubleshooting, we can ensure that our leak testing procedures remain reliable and effective, contributing to the safe and efficient operation of various systems and processes.